Table of Contents

Spyderco, Inc. is known for its quality knives, all over the world. The company was established in 1976 by Sal Glesser, and it continues to do great business. Spyderco has set the standard for folding knives. In the course of 40 years of operation, Spyderco has made significant contributions to the steel- & knife-making industries. It has innovated the use of certain blade steels, acquired a whopping 86 patents, kept its ear open to customers and collaborators, consistently improved its designs, and greatly affected other areas within that unique and ancient craft which is knife-making.

A knife is essentially a cutting tool. And what is it which constitutes a cutting tool? More often than not, it is a blade. And, when discussing blades, the blade’s steel is the most important factor. If the steel isn’t good, there is a good chance of the knife being a dud. It may have a handcrafted, gold-plated, diamond-encrusted, billion-dollar handle. But, if the blade is no good, it may turn out to be a glorified piece of junk.

This statement is not meant to knock anyone who uses low grade knives. Studies have shown that 9 out of 10 individuals who use a knife feel it should be made of materials which are not junk. Well, okay, I made that up, but the point remains – a quality knife should be made of high grade materials.

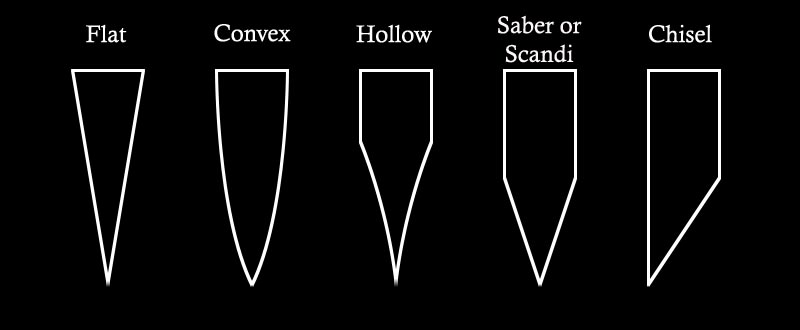

Spyderco offers knife models with different grinds on the blade. Varying blade properties are obtainable by changing the blade’s grind, which is why some models come with several grind options.

A blade’s grind is defined as “the shape of the cross-section of the blade”. Grinds differ, and they highly depend on what the blade is to be used for, as well as the material from which the blade is made. Much like blade steels themselves, there is no ‘best’ grind. The quality of a certain grind is completely subjective to its designated use.

Types of Blade Grinds

Hollow: The blade has bevels (slanted surfaces or edges) with a curve. It looks as though some of the steel has been hollowed out, which is why it carries this name. The bevels may extend the full width of the blade (which would make it a full hollow grind) or only a portion of its width (which would make it a hollow grind). Due to their unique shape, hollow ground blades are known as excellent slicers. On the other hand, you wouldn’t want to use a hollow-ground knife for batoning or heavy chopping.

Full Flat: The blade has flat bevels. They extend from the spine all the way to the cutting edge. This grind has less drag when cutting, and it helps the knife weigh less. Many kitchen knife blades are made with a full flat grind.

Saber: Also called a V grind. It is a blade ground with flat bevels that extend from the centerline of the blade to the cutting edge. It resembles a flat grind, but instead of it being flat from the spine, it becomes ground from the middle. This grind has a big advantage – because the grinding only begins halfway, it maintains a full thickness through the spine-to-middle portion of the blade, making it stronger and more heavy-duty oriented.

Chisel: Also called a single-bevel grind, this describes a blade that is beveled on only one side. It may be flat ground or hollow ground. The other side is completely flat, with no ground whatsoever. This polarizing grind is very common in Oriental kitchen knives.

Convex: It resembles the flat grind, only instead of the blade being flat, it is curved outwards. It has an arch-like shape. This means that there is a lot of material on it, extending from the spine all the way to the primary bevel, at which point it slants down to create the initial edge. The main benefit of this type of grind is the amount of strength that it carries. It is a heavy knife, and it can be used for heavy jobs. When properly sharpened, a convex-ground knife can be incredibly versatile.

Scandi: Also named ‘Scandinavian’ or ‘zero ground saber’, this grind is similar to a flat-ground saber, but without a secondary bevel at the cutting edge. The plane of the bevel continues to create the cutting edge. No angle changes are made to create an edge. In other words, that single bevel is one continuous edge. It makes it an excellent cutter and slicer, which is why is has been traditionally used in the harsher climates of Norway, Sweden, Finland, and other areas of Scandinavia.

Flase Edge / Wedge: A secondary edge (or potential for an edge) which is located at the spine of a blade, close to the point. If sharpened, it is called a false edge. If unsharpened, it is called a swedge. The main reasons for having it as part of the design are A) aesthetics, B) to lighten the weight on heavier blades, and C) a swedge improves the knife’s ability to penetrate.

Centerline: In a cross section, this blade would look like this: <>. It closely resembles a diamond. The grind is reminiscent of a double-edged knife, but only the bottom edge is sharpened. The spine of the knife is left unsharpened, and it creates a swedge.

Hamaguri: The name Hamaguri is Japanese for “clamshell”. It is a blade ground with convex bevels, and it is also called an Appleseed or Moran grind. This type of grind is produced by grinding on a slack grinding belt. It has very sharp edge and a very thick edge. This creates a knife with a sharp edge, which is also very durable.

Zero: A grind without the secondary bevel at the cutting edge. In this way, it is similar to a scandi. The plane of the bevel extends from the spine, then continues to create the cutting edge.

These are the main blade grinds which a user may encounter. There are some other ones, perhaps, but these are the most popular. As you can see, different grinds serve different purposes. Some are good for chopping and cutting, others for slicing and carving. Again, it is best to know what the designation of the knife will be, before settling on a specific blade grind.

The knife bevels are what lead towards an edge, but the edge itself could have one of several grinds. When it comes to Spyderco knife blades, they have their own trademarked names for the various edges.

Spyderco Edge Grinds Varieties

Plainedge – A smooth, continuous, sharpened edge with no serrations or teeth at any point. Also referred to as a ‘straight’ edge.

Spyderedge – An edge which has a two-step serration pattern: one large and two small serrations. This pattern increases the cutting edge’s surface area.

Combinationedge – A blade with an edge that is partially plain and partially serrated.

Trainer – A blunted blade which resembles its sharp counterpart, and is identical to it in terms of weight and proportion. This kind of blade is used for the purposes of training and practicing. Spyderco trainer knives are red-handled for quick and easy identification, and are a great companion for any self-defense class.

Like learning about all the newest gadgets? Our article about the latest and greatest glock 19 accessories will keep you up to speed.

No comments yet.